4.3 KiB

Recap of the Wheelchair Cushion Testing Rig Failure

Context

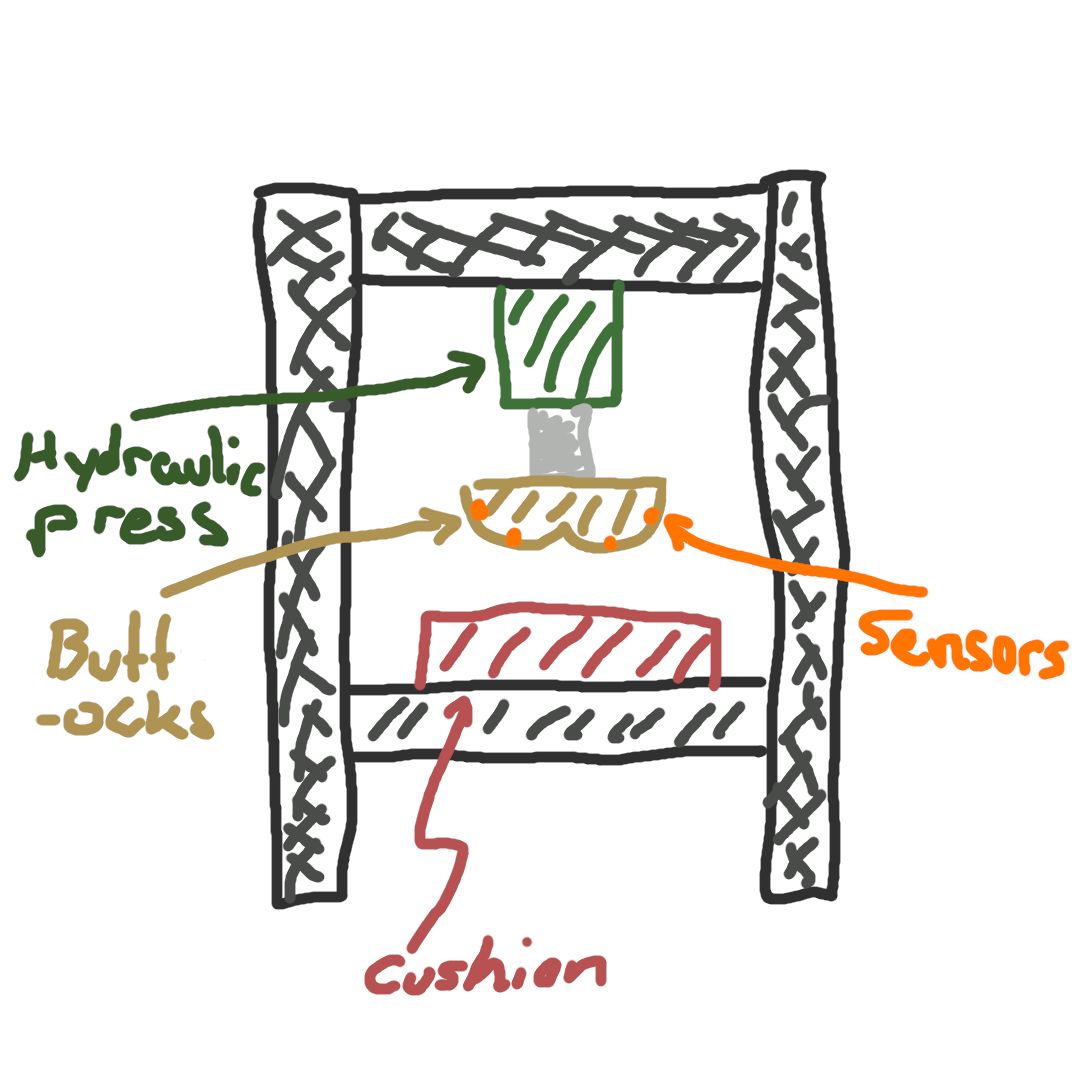

During a summer internship at Pitt’s Wheelchair and Cushion Standards Group, a friend of mine operated an ISO-16840-2 immersion test fixture designed to evaluate wheelchair cushions. The rig uses a hydraulic press fitted with a CNC-machined wooden “buttocks” model, instrumented with an array of pressure sensors, to measure both pressure distribution and press displacement as cushions are compressed.

Fatigue Test Incident

In a cyclic fatigue test, the press descends until a target pressure is reached, holds, then retracts to zero, repeating many times. When testing a cheap, air-mattress-style cushion, the material never achieved the setpoint. The controller attempted to compensate by increasing displacement, triggering an over-pressure safety retraction. Because the control logic was not designed for cushions that cannot reach the target pressure, it then aggressively re-applied the previous displacement. This rapid cycle of over-loading and retraction violently rammed the wooden model into the steel frame, quickly breaking the lower sensors and, after only a few seconds, splitting the wooden buttocks apart under what was later estimated to be well over 1,000 lbf (far above the intended 400 lbf). The test only stopped when the emergency-stop button was finally engaged.

Key Cyber-Physical Failures

-

Unvalidated Operating Envelope: The pressure-based controller was never formally verified for use with cushions that fail to meet the target pressure, allowing it to drive the system into an unsafe region.

-

Faulty Assumptions About Sensor Integrity: The over-pressure protection assumed sensors would continue to report accurately under extreme loading; as sensors degraded, the controller applied even more force.

Consequences

No one was injured, but the incident incurred high costs: replacing the CNC-machined buttocks model, purchasing new pressure sensors, and dozens of hours spent recalibrating and re-testing. This failure highlights the importance of high-assurance methods—such as formal proof of safe operating bounds and rigorous digital engineering—to guarantee that a CPS cannot drive itself into a destructive mode, even under sensor faults or unexpected material behavior.

So, how could rigorous digital engineering solve this problem?

The fundamental problem with this testing set up was not a implementation problem. The controller as it was programmed performed the fatigue test exactly as it was asked. Instead, this cyber-physical system failure starts before implementation and instead at the design stage. The designers of this system never properly examined the possible states this system could experience, or provided an opportunity in their design for their assumptions to be violated.

Here's a simple example. One of the main causes of the failure was that the control system could not reconcile that different pressure sensors may have wildly different readings. This makes sense for cushions that are operating properly where load would be evenly distributed, but cases where this assumption is violated were never examined. In the case of this failure, this assumption was violated by a subpar cushion, but what if a sensor was never connected to the system? Presumably, the testing fixture would behave this way regardless of the cushion being tested, and situations where sensors may disconnected briefly for cleaning or moving the fixture may be extremely common scenarios.

After taking the HACPS class, I think the designers of this testing fixutre could have made good use of a model checker like TLA+. An analysis of testing system through a series of TLA+ modules could avoid these disaster scenarios where sensors do not prompt correct control. One could do this analysis by examining what 'correct' behavior is:

For the testing fixture as described, a couple things should ALWAYS happen:

- The sensors on the bottom of the buttocks should ALWAYS experience more load than the sensors on the side of the buttocks

- The sensors on the bottom of the buttocks should never have a difference

in pressure from the side buttocks sensors greater than some value

\Delta P. - Sensors across symmetries (left vs. right buttock) should also always have similar values to one another.

How do these